|

|

|

|

|

|

|

|

|

|

|

JET CHAM

was established in Taiwan in 1985.

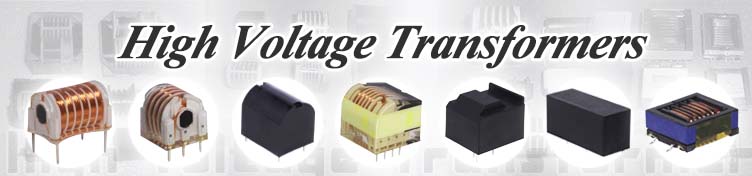

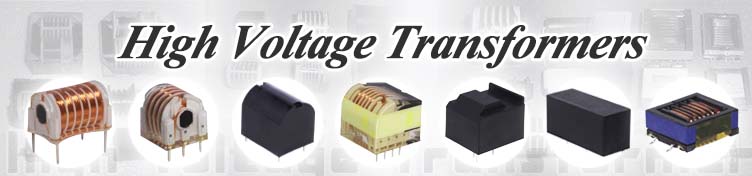

JET CHAM is a professional

manufacturer engaged in the R&D, production of High Voltage Trigger

Coil、High Ignition Coil and High Voltage Transformers. We accept OEM

& ODM.

Our products are wildly applied to Oil Ignition, Gas ignition, Air

Cleaner, Ozonizer, Hid Xenon Lamp Starter, Neon Lamp Starter. Plus,

each kind of High Voltage Ignition to other specified applications.

High Voltage Coil is our mainly product to develop, and take the

development of High-Voltage coil products around the world as the

direction.

Our well-equipped facilities and strictly quality control throughout

all stages of production. 30- years in service, Jet Cham has

received great reputations from home and worldwide clients.

Please feel free to contact us if you need more details. We are

looking forward to forming successful business relationships with

new clients around the world in the near future.

台灣捷群成立於1985年。

捷群是一家擁有高壓觸發線圈、高壓點火線圈、高壓變壓器研發能力及生產的專業製造商,我們提供OEM及ODM服務以符合客戶需求。

我們的產品被廣泛的應用於各式電子高壓模組,例如:空氣淨化產品中的負離子、臭氧、靜電高壓。

燈類產品中的霓虹燈、高壓燈、HID燈,以及高壓點火產品中的各種瓦斯、油類、氣體點火應用。

高壓線圈是我們的主要開發產品,並以全球高壓線圈產品的開發為方向。

我們有齊全的設備和嚴謹的品質管制,服務長達30多年的捷群已得到國內外客戶的好評及認可。

如果你需要更進一步的資訊,請不吝聯繫我司,我們期待在不久的將來與您共同創造美好商機。

What is a High Voltage Transformer?

A high voltage transformer is a type of transformer that operates at a high voltage level. High voltage transformers are normally used in high voltage labs for testing purposes. These high voltage transformers are subjected to transient voltages and surges during their normal operation when the insulation under test breaks down.

To withstand these impulse voltages, the insulation of these transformers must be carefully designed. These are usually single-phase core-type transformers.

This type of transformer is generally oil immersed. Bakelite sheets are used for separating high tension and low tension windings. The high voltage transformers used for HV cable testing also need to supply sufficient electric current.

This can generate a lot of heat, and as such the cooling system of these transformers is very carefully designed. Special care also needs to be taken to ensure proper transformer voltage regulation.

For insulator testing purposes, the required current is very less but, while the insulator breaks down during testing, there would flow huge current through the transformer. To limit this current, a high resistance is connected in series with transformer.

|

|

|

|

JET CHAM

ENTERPRISE CO., LTD.

3F. NO.41 CHIAU AN ST. CHUNG HO DIST 23557, NEW TAIPEI

CITY, TAIWAN R.O.C.

OFFICE TEL: 886-2-29253396 ~ 7

FAX.:886-2-29288877

FACTORY TEL: 886-2-22447326 ~ 7 FAX.:886-2-22447328

E-mail:

jetcham@ms35.hinet.net;

jetcham.coil@msa.hinet.net |

What is a high voltage coil?

High Voltage Coils High voltage coils are electrical coils that use a voltage higher than what is generally accepted as safe. High voltage refers to a currency that is potentially dangerous due to the possibility of sparks in the air and a possible electric shock to those in contact with the coil or in close proximity.

noun Electricity. a transformer for producing high-voltage alternating current from a low-voltage direct current, consisting essentially of two concentric coils with a common soft-iron core, a primary coil with relatively few windings of heavy wire, and a secondary coil with many turns of fine wire.

Can low voltage convert to High Voltage?

If a high voltage needs to be generated from a low voltage, a boost converter can be used. This represents one of the three elementary switching regulator topologies and requires only two switches, an inductor, and input and output capacitors. ... Boost topology for generating a high voltage from a low voltage.

What are high voltage capacitors made of?

High voltage capacitors with leads on four sides are often packed in trays or rails that are made of carbon-powder or fiber materials and molded into rectangular outlines that contain matrices of uniformly spaced pockets.

High voltage transformers convert voltages from one level or phase configuration to another, usually from higher to lower. They can include features for electrical isolation, power distribution, and control and instrumentation applications. This kind of transformer design depends on the principle of magnetic induction between coils to convert voltage and/or current levels.

What is a high voltage transformer?

High voltage transformers convert voltages from one level or phase configuration to another, usually from higher to lower. They can include features for electrical isolation, power distribution, and control and instrumentation applications.

How does a high voltage transformer work?

The core of the transformer works to direct the path of the magnetic field between the primary and secondary coils to prevent wasted energy. Once the magnetic field reaches the secondary coil, it forces the electrons within it to move, creating an electric current via electromotive force (EMF)

Why do transformers use high voltage?

When a current flows through a wire some energy is lost as heat. The higher the current, the more heat is lost. To reduce these losses, the National Grid transmits electricity at a low current. This needs a high voltage.

These transformers are installed at relay points in the transmission of electricity produced at power stations to consumers (such as households and factories).

In addition to extra-high voltage (EHV) and high voltage (HV), they offer practical use of ultra-high voltage (UHV) transmission of up to 1000 kV.

What is a High Voltage Transformer?

A high voltage transformer is a type of transformer that operates at a high voltage level. High voltage transformers are normally used in high voltage labs for testing purposes. These high voltage transformers are subjected to transient voltages and surges during their normal operation when the insulation under test breaks down.

To withstand these impulse voltages, the insulation of these transformers must be carefully designed. These are usually single-phase core-type transformers.

An ignition coil (also called a spark coil) is an induction coil in an automobile's ignition system that transforms the battery's voltage to the thousands of volts needed to create an electric spark in the spark plugs to ignite the fuel. Some coils have an internal resistor, while others rely on a resistor wire or an external resistor to limit the current flowing into the coil from the car's 12-volt supply. The wire that goes from the ignition coil to the distributor and the high voltage wires that go from the distributor to each of the spark plugs are called spark plug wires or high tension leads. Originally, every ignition coil system required mechanical contact breaker points and a capacitor (condenser). More recent electronic ignition systems use a power transistor to provide pulses to the ignition coil. A modern passenger automobile may use one ignition coil for each engine cylinder (or pair of cylinders), eliminating fault-prone spark plug cables and a distributor to route the high voltage pulses.

Ignition systems are not required for diesel engines which rely on compression to ignite the fuel/air mixture.

What does the ignition coil do?

All ignition systems for modern petrol engines use ignition coils for the same basic function: to create the high voltage required to produce a spark at the spark plug.

How much is a set of ignition coils?

Ignition coils are available in sets, which can cost anywhere between $50 and $300. Labor cost for an ignition coil replacement typically ranges between $100 and $120.

IGNITION COILS

Designed and manufactured in our ISO 17025 accredited lab, NGK ignition coils are engineered to OE durability and performance.

With more than 494 ignition coil part numbers and 95% VIO coverage, NGK is The Ignition Specialist™.

|

|

|

|

|

|

|

|

|

|